Elgi Equipment: Groundbreaking STABILISOR Technology for Air-Compressor

Air Compressors manufacturing major, ELGi Equipment’s groundbreaking STABILISOR Technology is setting new standards in Compressed Air Reliability, Energy Costs, and Variable Flow to drive efficiencies in compressor performance, inform Dr. Jairam Varadaraj, Managing Director, and Dr. Venu Madhav, Director Technology. NBM&CW reports on the launch.

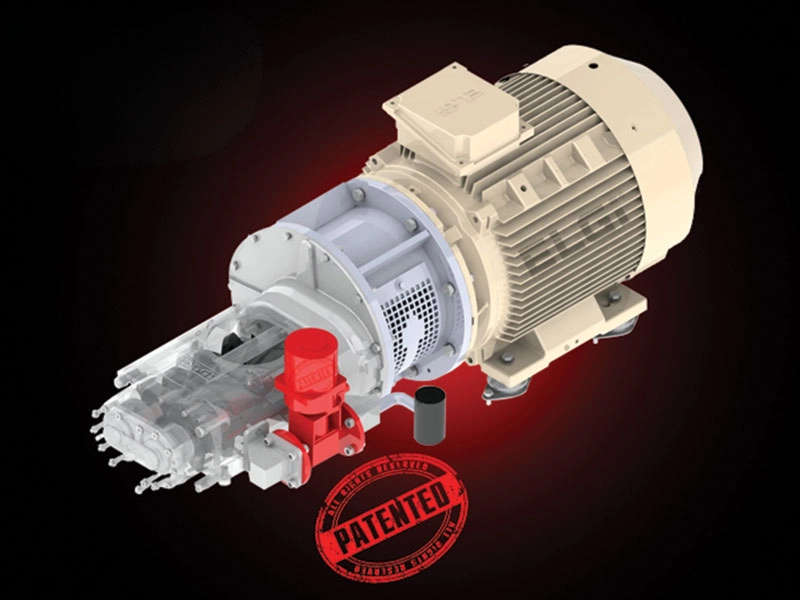

In a significant leap forward for industrial air compression, Elgi Equipments, one of the world's leading air-compressor manufacturers with over 64 years of compressed air excellence, has introduced its pioneering compressed air stabilization technology. Designed to revolutionize the way compressors operate in plants with dynamic air demand, the STABILISOR system aims to address the longstanding challenges of unstable compressor performance, inefficiency, and excessive wear caused by frequent load/unload cycles.

In industrial settings, the gap between compressor capacity and plant air demand is inherently dynamic. This variability leads to frequent cut-in and cut-out operations, which destabilize the compressor and impair critical flow and kinematic components. Traditional solutions, such as increasing reservoir volume, altering cut-in/cut-out pressures, or adding variable frequency drives (VFDs), often fall short, introducing new inefficiencies or higher operational costs.

Dr. Jairam Varadaraj, Managing Director, Elgi Equipments, informs, “The STABILISOR system employs a first of its kind "Recirculate and Recover" principle, seamlessly aligning compressor capacity with plant air demand through controlled recirculation and recovery techniques. By stabilizing airflows within the system, the STABILISOR system minimizes load/unload cycles, ensuring extended equipment lifespan, optimizes energy use, achieving up to 15% energy savings in typical applications, while reducing system inefficiencies, maintaining superior performance across varying demand patterns. With its energy-efficient design and potential to reduce wear-and-tear, the STABILISOR aligns with global sustainability goals. Its implementation in industrial plants represents a shift towards greener, more cost-effective manufacturing processes.”

Says Dr. Venu Madhav, Director Technology, Elgi Equipments, “The STABILISOR system utilizes precision-engineered progressive and on-off valves to recirculate excess capacity within the system. This system leverages stabilization zones and low-pressure recovery techniques to - balance airflow demands dynamically, minimize energy losses by targeting pressure points with minimal differences all while maximizing overall system reliability.”

To meet diverse operational needs, the STABILISOR system will be available in India and across the globe in 2025 in two versions:

- Light Version: Designed for field fitment, energy savings and enhanced reliability.

- Heavy Version: Factory-fitted for superior energy savings and comprehensive stability.

The STABILISOR’s innovative design and control methodology has been patented worldwide, marking it as a pioneering advancement in compressed air technology. The solution is also aimed towards reducing ownership costs, energy efficiency, power and superior performance.

Dr. Venu Madhav, explaining the utility of the STABILISOR, says, "During the working of the compressor in typical plant, the gap between the compressor air supply and plant demand will cause unstable operations. This will generally result in efficiency and reliability challenges. Inverters or VFDs balances the gap to a fair extent. However, there will be still factors of instability in operations causing excessive fluctuations. This can impact flow of air, reliability and overall performance issues. Due to the instability in operations, there will be excessive fluctuations. Though VFD can address this, however, the inconsistency in airflow will be there, harming the electrical components, resulting higher operating costs. The unique STABILISOR technology addresses these gaps and brings in reliability in performance of the compressors. "

The STABILISOR system layout comprises two types of valves, one is progressive and the other is cut-off. These valves are precisely positioned to balance capacity and demand by recirculation. This technique and control ensure stable operations and energy recovery wherever possible, thereby ensuring optimal operation of the compressors.

On offering the stabilizers for the mineral processing sector for horizontal drilling operations in primary crushing, Dr. Varadaraj said, "So far we have been undertaking the trials on the stabilizers for the industrial applications. Trials have not been undertaken in portable in-situ machines, deployed in the mineral processing industry. However, there will be scope for fitment of the solution in portable compressors and we are exploring the possibilities. Based on the opportunities, we may look to offer the solution as a complete kit with the compressors or also as retrofittment product with eliminating the VFD. The stabilizer can be made to work with rotary, screw, or displacement compressor."

Dr. Varadaraj informs that the company has applied for a patent on the solution and commercial production will begin in another six months. “We will also provide training to our channel partners and to the users on the components of the stabilizers, their maintenance and service.

“We may further synchronize the operation of the stabilizers with the working of the main compressors. We will increase our production capabilities for compressors, for which we are already undertaking capacity expansion. We will be targeting the domestic market and also Europe, US, Australia, Indonesia, and Thailand, which constitutes 60% of the global export market for compressors."

Elgi, which holds sixth position, aims to rank amongst the top three compressor manufacturers, globally. It plans to invest Rs 650 crores during the next three years to increase its production capacity, and in research and development of more products that will bring in greater efficiency in compressor performance. “What differentiates our Stabilizor from our competitors is its premium quality, its initial cost competitive price, and the long warranty period,” avers Dr. Venu Madhav.

The company plans to increase the usage of compressors in granite and marble mines for drilling operations. "The marble industry in Rajasthan is one such prospective area for Elgi Equipments. We have a wide range of compressors in the portable category with various bar pressures for blast hole drilling. We also have solutions for the blue metal industry. Besides increasing performance, our products will lower the costs of operations. Use of electric machines in quarry, marble and granite mining also holds promise, which, however, will depend on uninterrupted electric supply and the cost,” says Dr. Varadaraj."

Elgi Equipments Limited's product offerings consist of oil free rotary screw, air compressors, oil lubricated, oil free reciprocating air compressors, centrifugal air compressors, dryers and filters.