High Performance Integral Waterproofing Solutions for Concrete by Assess Build Chem

Concrete has an affinity to water and therefore is a wettable material. Water enters concrete through continuous capillaries, either under hydrostatic pressure, or by capillary action. The porosity of concrete contributes greatly to ingress of water into the concrete. Thus, it is imperative that the concrete should be produced with a low permeability. This is where the usage of integral waterproofing / damp proofing additives comes into practice. This concept looks at the improvement of concrete or mortar (as a whole), and casting of impermeable concrete as the first barrier in the basement waterproofing system. The concrete itself can be improved by:

- Limiting w/c ratio to 0.4 – 0.45, by using suitable superplasticizing admixtures

- Improving impermeability by using a mixed mode [compaction improving, hydrophobic, crystalline and pore blocking] integral waterproofing admixture.

- Proper placing and compaction

- Using an acrylic based curing compound to cure the concrete and seal it safely at early ages

Figure: Integrally waterproofed basement raft, 8000 sqm+ in coastal zone

Figure: Integrally waterproofed basement raft, 8000 sqm+ in coastal zone

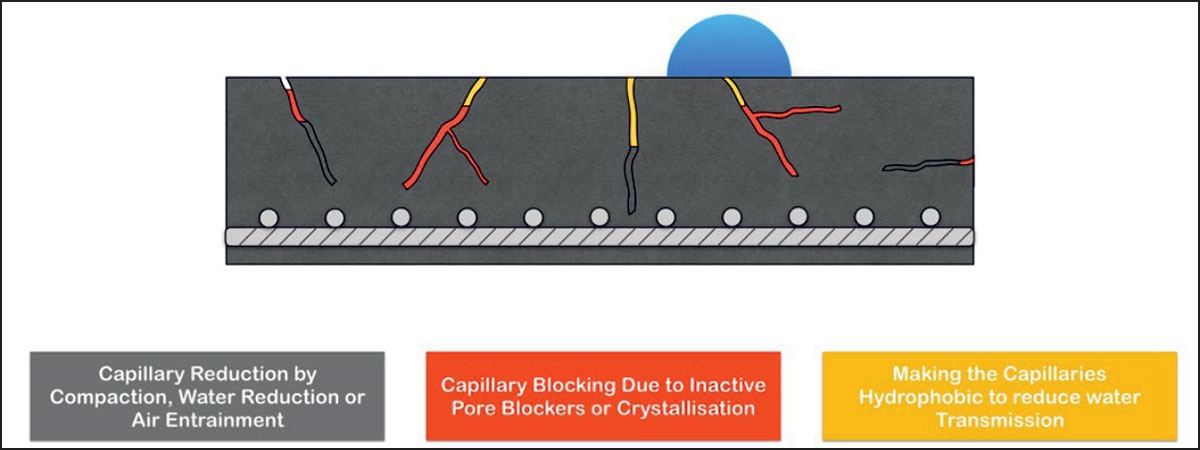

Modern Integral Waterproofing Additives function based on a synergistic combinations of the three mechanisms listed below:

Reduction of capillarity and compaction improvement: These additives improve workability at the same w/c ratio or provide a reduction in w/c at the same workability levels. This property helps concrete achieve excellent compaction and denser hydration (C-S-H Gel Formation) thereby reducing capillary pores to improve water resistance.

Making capillaries hydrophobic: This is achieved by using modern hydrophobic additives. These materials react with the alkaline cement constituents and form insoluble hydrophobic by-products that line the pores. This renders the capillaries hydrophobic, preventing capillary absorption and keeping the concrete dry.

Pore Blocking (physically and crystalline): Modern integral additives achieve physical pore blocking with finely divided expansive mineral additives. When hydrostatic pressure is applied, these finely divided materials swell and are pushed into the capillaries, forming a physical plug, preventing penetration of water. Crystalline pore blocking is achieved using advanced micro-fine reactive silicates or pozzolanic nanoparticles to enable secondary hydration. This enables densification of the C-S-H gel and transition zones between cement matrix and aggregates on a nanoscale. A well-designed synergistic combination of these properties in an integral waterproofing additive provides maximum protection to concrete, rendering concrete watertight.

Figure: Working Mechanisms for Integral Waterproofing Additives

Figure: Working Mechanisms for Integral Waterproofing Additives

Why Choose SS - ConProof CR?

As a solution, SS - ConProof CR, the high-performance, crystalline, hydrophobic, and pore-blocking integral waterproofing additive for concretes and mortar, meets this requirement and more.

- Crystalline Action: Forms waterproof compounds within the mix, ensuring deep and lasting protection.

- Hydrophobic Properties: Blocks water ingress through capillaries and cracks.

- Enhanced Workability: Improves mix compaction and homogeneity.

- Non-Toxic: Chloride-free and safe for all environments.

- Economical Dosage:** Efficient and cost-effective.

Applications

- Indoor areas: Bathrooms, kitchens, and wet spaces.

- Basements: Walls and floors.

- Water structures: Tanks, pools, and canals.

- Underground structures: Footings, lift pits, and metro rails.

- Damp masonry: Waterproof renders and plasters.

To know more contact: