Macons Innovates With Affordable Concrete Block Making Machine

A Pioneer in Indian Manufacturing

Introducing Concrete Block Making Machine

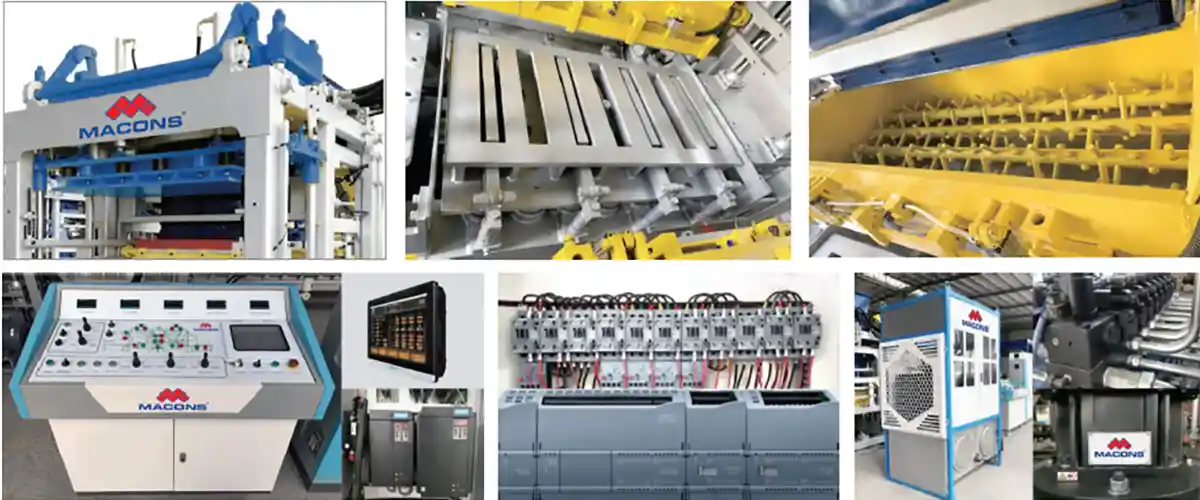

Macons Equipments has expanded its product portfolio with the introduction of a Concrete Block Making Machine. This machine boasts a German-standard main frame and vibrator, ensuring enhanced productivity, minimal maintenance, and extended lifespan. Available in four models with configurations ranging from 4 to 12 hollow bricks per pallet, the machine’s versatility can suit various construction needs.

Key Features

The Concrete Block Making Machine has cutting-edge features such as an efficient vibration technology, a rapid-feeding mechanism, intelligent frequency conversion technology, a Siemens control system, and a servo hydraulic system. These features collectively enhance performance, efficiency, and user-friendliness, setting a new standard in concrete block production.- The main frame of the machine has a German standard high–load square tube structure, which fully meets the basic requirement of high vibration force, fast feeding time, and long life.

- The machine has the most advanced German vibration technology. The Vibration table consists of a dynamic table and a static table, which greatly improve the vibration efficiency to produce a high-quality concrete product.

- The feeding time is short as the system has a 360° fast feeding. The Feeding Box of the machine uses two SEW feeding motors which control the mixing shafts.

- The machine is integrated with the most advanced industrial technology that offers advantages such as remote modules, touch screen operation, automatic trouble shooting and easy maintenance.

- A Siemens PLC and Siemens control panel for electric control ensures high stability, a low failure rate, and easy maintenance.

- The machine’s Hydraulic System consists of a servo motor and a servo pump that control the feeding response and independent movement, while separate control valves intelligently improve the running speed, making it fast, smooth and more efficient.

Published on:

Published in: NBM&CW - March 2024

Share:

We Value Your Comment