Promax’s ‘Quarry to Bag’ Approach Redefining Quality and Control in Drymix Manufacturing

"With our ‘Quarry to Bag’ concept, we don’t just make products; we control the process, ensuring unmatched quality, consistency, and sustainability from the ground up, and shaping the future of construction through quality, innovation, and trust."

Sreenivas, CEO, Promax Drymix & Construction Chemicals Co.

How is Promax Drymix positioned in the competitive construction chemicals space?

Promax Drymix holds a distinct position in the construction chemicals industry, driven by superior quality, continuous innovation, and indigenous manufacturing expertise. Our proprietary "Quarry to Bag" approach ensures in-house control from raw materials to final packaging, guaranteeing consistency and quality. As a truly Indian brand, we bring global best practices to the local market while supporting the Make in India vision. Leading the way for sustainable, green building products, all product formulations are 100% M-sand based.

How has your international experience shaped your journey with Promax, particularly in overcoming challenges in the Indian market?

With over two decades of experience in the Drymix industry, including key roles in UAE and the GCC with Global MNCs, I had the opportunity to introduce machine plastering in the Middle East as early as 2003. This global exposure has equipped me with a deep understanding of advanced construction technologies and best practices.

When I brought this expertise to India through Promax, I found the market faced several challenges: fluctuating raw material quality, labor dependency, and low awareness of modern Drymix solutions. To address these, we focused on innovation, strategic raw material sourcing, and extensive training programs. By educating contractors and applicators on efficient, high-performance systems, we’ve been able to bridge the gap between international standards and local needs—delivering world-class solutions tailored for India.

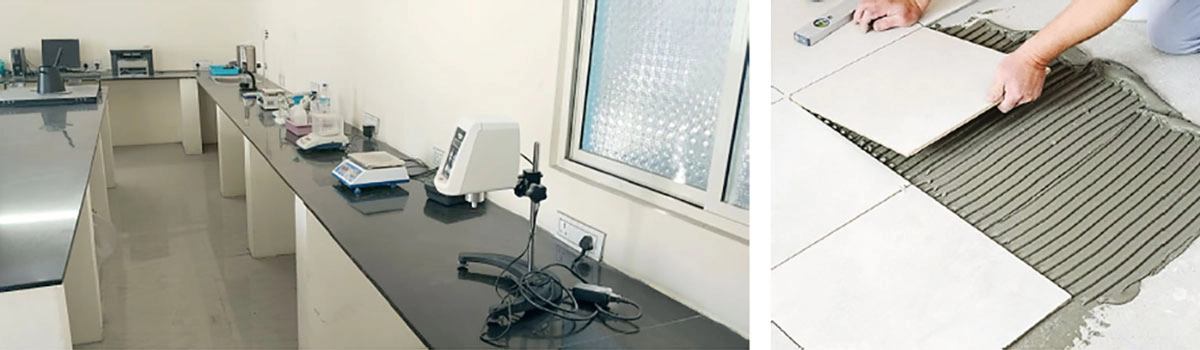

What sets Promax apart in manufacturing and technology?

We design and develop our own manufacturing systems, enabling state-of-the-art drymix plant concepts that support seamless production of a wide variety of products. Our robust R&D and stringent quality control processes ensure consistently high product quality. Additionally, our technical team offers training and on-site support to industry professionals, while innovations such as our thin bed single coat plaster and machine spray plaster further strengthen our technological edge.

What does your product portfolio include?

Our range covers:

- Renders & Plasters (including machine sprayable)

- Block Jointing Mortars

- Tile Adhesives

- Thin Bed Renders (crack free & self-curing) & Floor Screeds

- Non-Shrink & Anchor Grouts

- Dry Concrete, Dry Shake Hardeners, Micro Concrete

- Keycoat (eliminates hacking)

All product formulations and performance comply with IS and BS standards, ensuring reliability and performance backed by competent 3rd party lab reports.

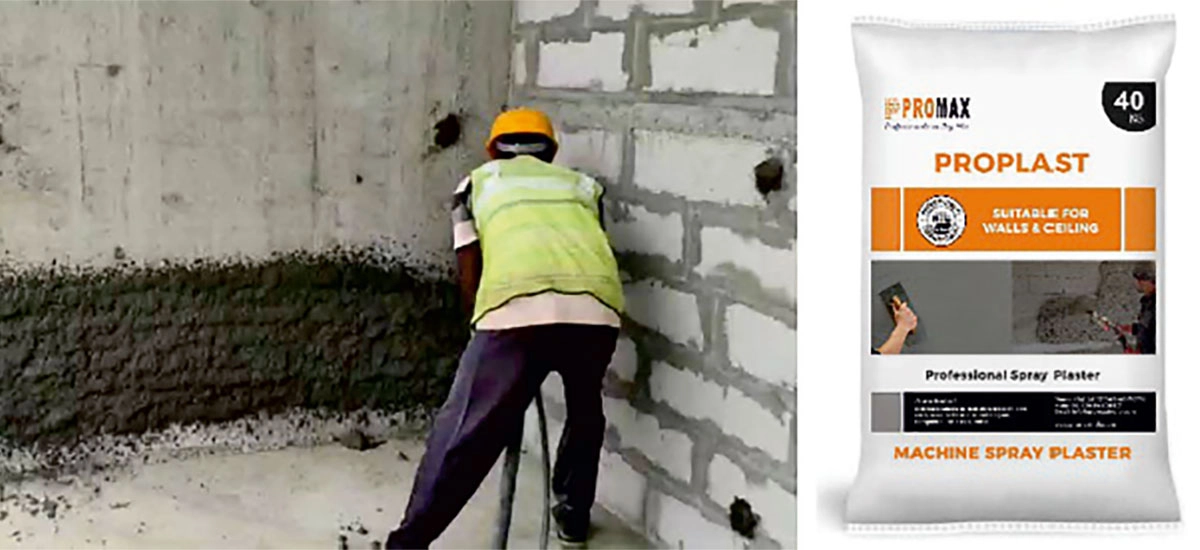

How is your Machine Spray Plaster transforming plastering?

Our Machine Spray Plaster significantly enhances efficiency by minimizing manual labour, enabling faster application, and delivering a superior surface finish, all while reducing material wastage. This advanced technology, well-established in Europe and the Middle East, is now redefining plastering practices in India. We believe it represents the future of plastering in the construction industry, offering both speed and consistency that traditional methods cannot match.

What key qualities make Promort RMP a preferred choice in the market?

Promort RMP (Ready-Mix Plaster) delivers exceptional workability, smooth finish, and reliability under various site conditions. It provides a hassle-free, high-performance solution preferred by contractors and developers as it is self-curing & crack free.

How does Promax ensure sustainability?

We focus on eco-friendly production, optimizing energy use, reducing waste, and sourcing sustainable raw materials. Our "Quarry to Bag" system ensures efficient resource utilization with minimal environmental impact contributing handsomely to the sustainability goals and “green buildings”.

How does technology contribute to Promax’s growth, and in what ways do you support customers beyond just product delivery?

Technology is at the core of Promax’s growth strategy. Our automated manufacturing systems and advanced product formulations enhance both efficiency and consistency. A great example is our machine spray plaster, which significantly boosts productivity while ensuring high-quality finishes.

But our commitment doesn't end with product delivery. We provide comprehensive customer support through expert training sessions, on-site technical assistance, and customized solutions. This ensures that our products are applied correctly and perform to their full potential—leading to long-term satisfaction and success for our clients.

What are your expansion plans for the future?

We’re expanding our footprint across Karnataka, and other parts of India, with a focus on strengthening our presence in both metropolitan and tier-2 cities. Looking ahead, we’re also exploring strategic collaborations with quarry operators, which will allow us to diversify our offerings and enter new market segments with strong growth potential.