Trimble Solutions: Machine-Controlled Construction Technologies

Harsh Pareek, Regional Sales Director, India and SAARC, Trimble Solutions, discusses the benefits of machine-controlled construction technologies and modern building methods in India; digital integration for project management and decision-making in large-scale infrastructure projects; and how the barriers to their adoption can be addressed.

What makes accelerating road construction critical for India's development, and how is the country performing on this front?

India’s road infrastructure plays a pivotal role in driving economic growth, national connectivity, and regional inclusivity. With one of the largest road networks globally, the country has consistently expanded its highways to bridge urban and rural divides, facilitate trade, and improve access to essential services. In FY 2023–24, India constructed approximately 12,300 km of national highways—an average of nearly 34 km per day. Though slightly behind the record 13,327 km achieved in 2020–21 during the pandemic, this performance remains a testament to India’s resilience and commitment to infrastructure development.

Faster road construction is not merely about meeting numerical targets; it directly influences the efficiency of logistics, reduces vehicle operating costs, and enhances safety. It also plays a strategic role in national security and disaster response, enabling quicker troop movement and relief operations. However, as construction volumes rise, so do the complexities. Meeting ambitious goals requires a shift toward intelligent, data-driven construction methods that ensure both speed and quality. That’s where emerging technologies, particularly machine-controlled construction equipment, are becoming essential. These tools don’t just speed up work—they also reduce human error, improve sustainability, and support long-term infrastructure durability.

How are machine-controlled construction technologies transforming traditional road building methods in India?

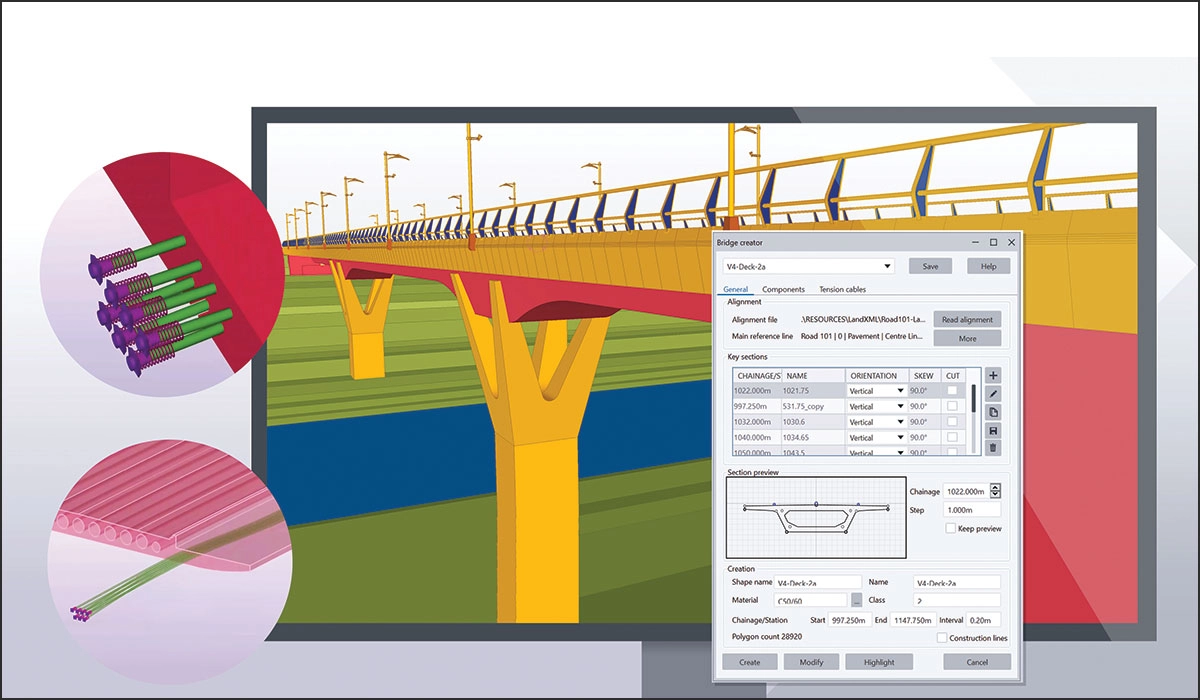

Traditional road construction methods in India, though functional, have often been plagued by inefficiencies. Challenges such as human error, uneven grading, rework, and inconsistent progress tracking have led to project delays and inflated costs. The integration of machine-controlled equipment—powered by GPS, real-time sensors, and automation—marks a paradigm shift in how road infrastructure is built.

These systems bring precision and quality to tasks like grading, paving, compaction, etc. Technology ensures machines are intelligent enough to understand design and hydraulics are automated, ensuring blade or screed consistency with involvement of manual guidance, thus eliminating errors and reducing the need for rework. The result is not only faster project timelines but also superior road quality, reduced material wastage, and less wear and tear on machinery. Moreover, these technologies reduce physical fatigue among workers by limiting repetitive manual interventions and enabling more ergonomic operations.

What’s truly transformative, however, is the ability to sync these machines with digital project models in cloud platforms in a two-way communication between office and field. Engineers and managers can now visualize work progress in real time, diagnose issues early, and adjust schedules dynamically. This level of integration supports a culture of proactive, rather than reactive, project management. In a country like India—where varied terrains, monsoons, and land acquisition hurdles pose additional challenges—this tech-driven approach introduces much-needed resilience and flexibility into the construction process.

Please share real-world examples of projects where machine-controlled technologies have significantly improved outcomes.

There have been multiple expressways which have used GNSS based Automated Machine Guidance Technology to speed project deliveries significantly. One such expressways is Kanpur-Lucknow Expressway that stands out as a prime example of how advanced construction technologies are revolutionizing infrastructure projects in India. This project has a special significance as it was the first project in India where technology was acknowledged and mandated by NHAI on Graders, Pavers and Compactors. This is a 63-kilometer, six-lane (expandable to eight) access-controlled highway connecting Lucknow and Kanpur in Uttar Pradesh. The project is nearing completion and is expected to reduce travel time between the two cities from 1.5-3 hours to 35-40 minutes. This expressway is considered a significant infrastructure initiative for the region, aiming to facilitate faster and smoother intercity travel.

Trimble’s GNSS-based systems and machine-controlled construction equipment played a crucial role in this project execution to significantly improve the quality and established a real time monitoring during project execution. Real-time 3D control allowed for exact slope alignments and layer thicknesses, significantly reducing material wastage, rework, and construction errors. There has been a significant involvement from authorities (NHAI and Road Ministry) in this project, who have acknowledged the significant benefit the Automated Machine Control Technology has brought to this project execution.

In what ways is digital integration changing project management and decision-making in large-scale infrastructure projects?

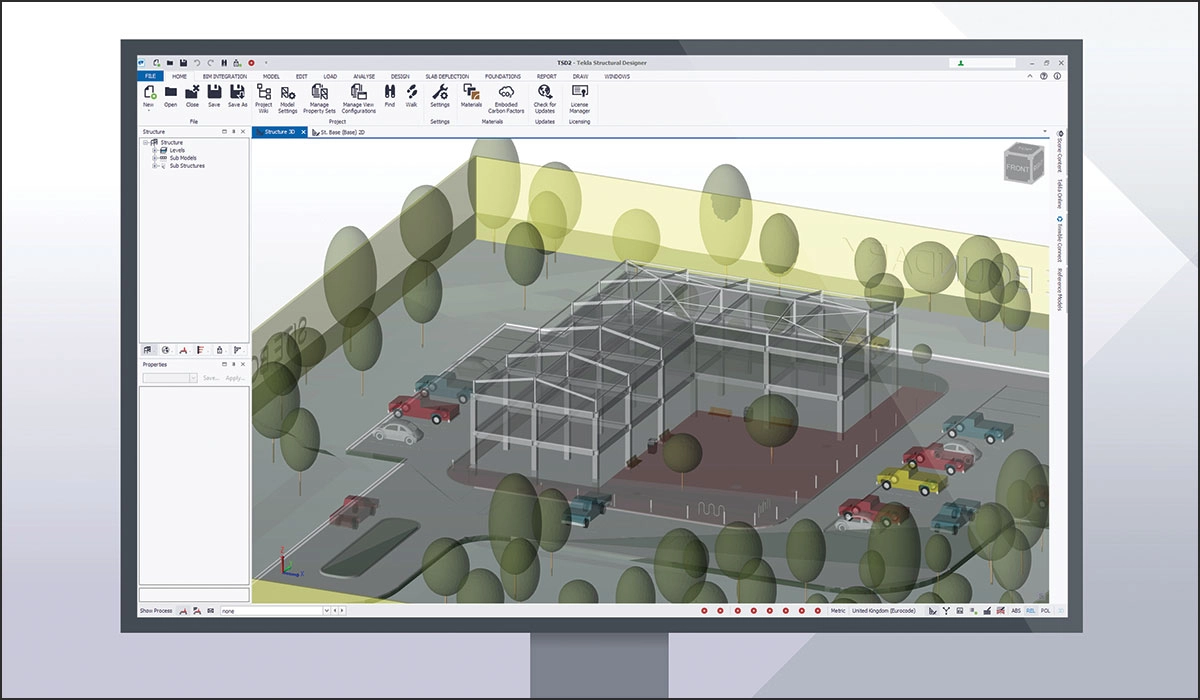

Digital integration is redefining how infrastructure projects are managed—from the drawing board to execution. By combining machine-controlled systems with centralized data platforms, project teams now have access to real-time insights that were previously difficult to obtain through manual supervision.

Technologies such as GPS-enabled equipment and 3D modeling software allow engineers and managers to monitor progress with precision. This means potential issues can be flagged early and addressed before they escalate into costly delays or design mismatches. Real-time updates also enable smarter resource allocation and better coordination among on-site teams, equipment, and decision-makers.

In recent projects, even minimal use of centralized monitoring—where data from machines is relayed to a control center—has made a big impact. It allows for live tracking of daily progress, enhances accountability, and reduces the need for manual oversight. Over time, these systems create a robust feedback loop that helps refine future project planning and risk assessment.

Ultimately, digital tools bring greater transparency and predictability to infrastructure development. They help unify all stakeholders—engineers, contractors, and policymakers—on a shared platform, making it easier to adapt to challenges and meet delivery targets efficiently.

What long-term goals is India aiming to achieve through improved road construction, and how does machine control align with them?

India’s road-building efforts are about far more than just creating highways. At a strategic level, they aim to foster economic inclusion, improve supply chain efficiency, and enhance regional connectivity. Roads are lifelines that tie agricultural regions to markets, manufacturers to ports, and remote communities to healthcare and education. The goal is an integrated, pan-India logistics network that minimizes transit delays, lowers costs, and supports sustainable growth.

To achieve this, construction processes must be faster, more precise, and less resource-intensive. Machine-controlled equipment aligns perfectly with these aspirations. By reducing rework, optimizing material usage, enhancing build quality, such technologies support the creation of long-lasting infrastructure that requires less maintenance over time. This not only lowers lifecycle costs but also reduces environmental impact.

In the long term, the adoption of machine control and digital construction methods can serve as the foundation for more advanced capabilities like AI-based planning, autonomous machinery, and predictive infrastructure maintenance. As India moves toward a $5 trillion economy, infrastructure must keep pace—both in scale and sophistication. Machine-controlled construction is not just a tool for today’s challenges but a building block for the smart, connected transport systems of the future.

What barriers exist in scaling machine-controlled construction equipment across India, and how can they be addressed?

Despite the promise, there are clear challenges in scaling machine-controlled equipment across India. Though the ROI for high-tech construction machines and GPS-based control technology is very high and the investment can be recovered in just 6 to 7 months, it requires significant initial investment—something that smaller contractors may struggle to afford. Additionally, integrating these technologies into existing workflows requires a cultural shift in how construction teams operate and think.

Another hurdle is the skill gap. Operating machine-controlled equipment is not about pushing a few buttons; it demands an understanding of digital models, real-time feedback systems, and precision handling. Many workers, especially in Tier 2 and Tier 3 cities, have limited exposure to such technologies. Without proper training and support, adoption will be uneven.

The good news is that both central and state governments are beginning to address this through targeted skilling programs and public-private partnerships. Equipment manufacturers are also offering user-friendly platforms and training modules tailored to Indian market conditions. In parallel, government tenders could increasingly mandate technology use, creating demand and building momentum across the sector.

Ultimately, widespread adoption will depend on a collaborative effort between industry players, policymakers, and educational institutions. If done right, it will not only improve project outcomes but also upskill India’s construction workforce for a tech-driven future.