Progress Group's SPI Process: Redefining Precast Concrete with 3D Printing

3D Concrete Printing in a new dimension, is redefining precast possibilities with layer-by-layer precision

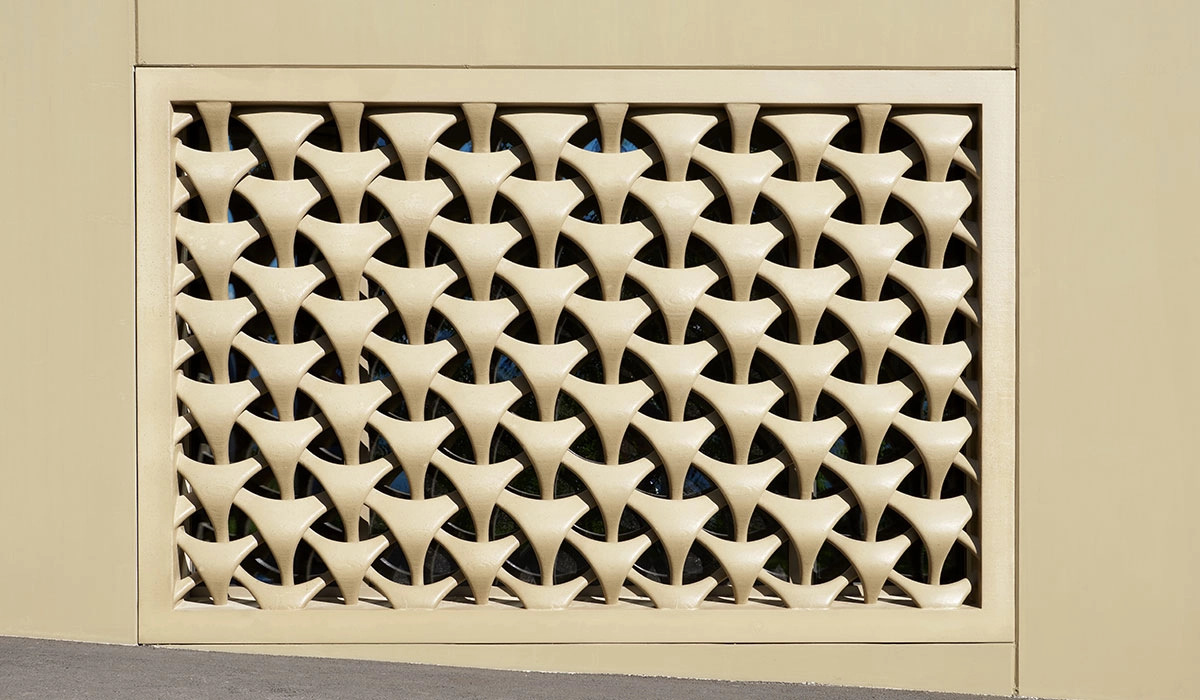

The Progress Group, a leading company in mechanical engineering and precast concrete production, has achieved a technological breakthrough with the development of its 3D printer for large-format use in the construction industry. The innovative SPI (Selective Paste Intrusion) process enables the production of concrete components with highest precision and attention to detail.

But SPI isn’t just a printing process: it’s a new language for concrete, enabling us to design and build in ways that were once unimaginable. It is also a transformative tool that empowers architects and engineers to push the boundaries of design, precision, and sustainability.

SPI: A new tool for the construction industry

At the Progress Group's 3D printing center in Brixen, South Tyrol, individual components are created every day, from customer-specific products to innovative prototypes. The SPI 3D printer, which was developed in the company's research and development department, works with a resolution of just three millimeters per layer, enabling surfaces of the highest quality.

Freedom of shape and conservation of resources

The printer's job box, measuring 4m x 2.5m x 1m, opens up completely new possibilities in the design of buildings. The components created using 3D printing are characterized by a high degree of freedom of form and accuracy. The SPI process also enables a resource-saving construction method, as material is only used where actually needed.

Evolution instead of revolution

The Progress Group sees 3D printing in the construction industry as an extension of existing possibilities and not as a revolution in concrete production. 3D printing makes particular sense where complex moulds or small batch sizes are required, which could otherwise only be produced at a great expense. Applications that have already been realized include façades, balconies, formworks, and special prefabricated elements.

SPI: No competition for 3D concrete printing on the construction site

In contrast to the common image of 3D printing houses directly on the construction site, the Progress Group is focusing on the production of precast concrete elements in the factory. This method offers numerous advantages such as working independently of the weather, better quality control, and optimized working conditions.

Julius-Durst-Straße 100, 39042 Brixen, Italien

T +39 0472 979