Weichai: High-Performance Engines for Construction & Road Machinery

Gurunath Kulkarni, VP - India Operations

Gurunath Kulkarni, VP - India OperationsHow does Weichai ensure the performance, reliability, and suitability of its engines for various construction and road machinery applications?

Weichai is a global leading player in diesel and gas engines, committed to its brand promise of "Engineering Your Power." We manufacture engines that are with the latest technology, and reliability in diverse operational environments.

Each engine is developed with a careful selection of systems such as cooling, air intake, exhaust, and fuel management, tailored to the operating conditions of the site. This attention to detail enhances the durability and reliability of our engines, ensuring they meet regulatory compliance and perform well across a wide range of applications.

We supply our engines to major OEMs for use in loaders, graders, pavers, and compactors. We see a lot of potential in excavators and backhoe loaders which represent a larger market. Our firefighting equipment and collaboration with OEMs for compressor and pump further highlight our broad market presence.

One of the key strengths of Weichai engines is our rigorous R&D; for example, when developing an engine for a grader application, we ensure that the engine is specifically calibrated for that purpose, rather than altering load cycles or calibration settings. This results in engines that perform well in demanding applications, with low maintenance, minimal oil consumption, and an extended lifespan.

What sensor-based technology has Weichai incorporated in its engines?

At Weichai, we have integrated IoT-enabled technology across all our engine segments. The key is the use of sensor-based systems, which are not exactly IoT-based in the traditional sense but serve a similar purpose. By incorporating real-time diagnostics and fault monitoring, our engines communicate with diagnostic tools to provide detailed error codes and fault descriptions. This feature allows for quick troubleshooting, reduces service time, ensures optimal performance, and ultimately lowers maintenance costs.

How does Weichai address the challenges of fuel consumption and environmental concerns in its engine technology?

Fuel consumption and environmental concerns are two major issues being widely discussed in the industry today since they are critical to both engine manufacturers and R&D engineers. The challenge lies in ensuring fuel efficiency while reducing emission, without compromising one for the other.

At Weichai, we have focused on thermal efficiency for addressing both fuel economy and emissions. Our engines have achieved an impressive thermal efficiency rate of 56.06%, which allows for both performance and environmental sustainability. Reducing carbon emissions is another critical aspect of our approach. In diesel engines, after-treatment technologies such as catalytic converters play a significant role in emission control. These systems have evolved into more advanced, technology-oriented catalysts since the introduction of Stage 6.

Our presence across various industries and products provides a unique advantage. Having already achieved BS6 standards in various segments, moving to meet Stage 5 and CPCB 4+ standards becomes a more seamless process. This consistency across our product range helps ensure that we are meeting environmental expectations.

How does the engine cost impact the overall machine cost?

When it comes to cost, it's not as complex as it may seem. While engine costs will naturally increase, the impact on the overall cost of the machine is relatively manageable. For example, in a dump truck, the engine typically contributes around 18% of the total equipment cost. If the engine's contribution increases to 30%, it will result in only a 7% increase in the overall equipment cost. This 7% increase in cost is offset by the fuel efficiency improvements the engine provides, ensuring a favorable balance between cost and performance.

Weichai's engines have proven to be a popular choice among Indian OEMs, with many switching to our engines due to their exceptional performance in terms of fuel efficiency and operational reliability. Our loaders and graders, in particular, have gained strong recognition. Graders, being a tough application, are not easily mastered by most manufacturers, but Weichai has been successful in delivering high-performing solutions in this area.

What are Weichai’s plans for adopting hybrid and hydrogen fuel technologies?

Weichai is fully prepared for the future of hybrid, hydrogen, and alternative fuel technologies. Our engines are already running on hydrogen in countries like China, US, and France, and we have successfully implemented fuel cell technology. We also offer engines for electric forklifts, electric excavators, and electric dump trucks.

While hydrogen and fuel cell technologies are gaining attention globally, the adoption of these technologies (beyond small electric vehicles like two-wheelers and three-wheelers), remains limited. The primary challenge is the cost factor, as these technologies significantly increase the equipment cost. The rise in cost impacts not only the initial purchase price but also the overall expense of the equipment, making it more difficult for widespread adoption, especially in markets where cost considerations are critical.

How does fuel cleanliness impact engine performance and maintenance intervals?

At Weichai, we have adopted the industry standard of 500-hour maintenance intervals, and the reason for this is twofold: firstly, fuel quality has significantly improved over the years. To achieve optimal engine performance and longevity, it is crucial that fuel remains clean. Secondly, when clean fuel is used, less carbon is produced, which reduces the accumulation of carbon deposits in the engine oil. This helps maintain the oil's effectiveness and prevents excessive build-up on engine components.

We recommend testing engine oil at 400 and 500-hour intervals to check soot levels. If the soot levels are within the acceptable limits, operators can extend the maintenance interval by an additional 100 hours. However, this process requires careful monitoring.

A common issue we observe is when engines fail and become beyond economical repair, often due to contaminated fuel. Cleaner fuel can significantly extend engine life and maintenance intervals, ensuring smoother operation and reducing the need for premature repairs.

Please elaborate on Weichai's manufacturing capabilities in India and the level of localization achieved so far.

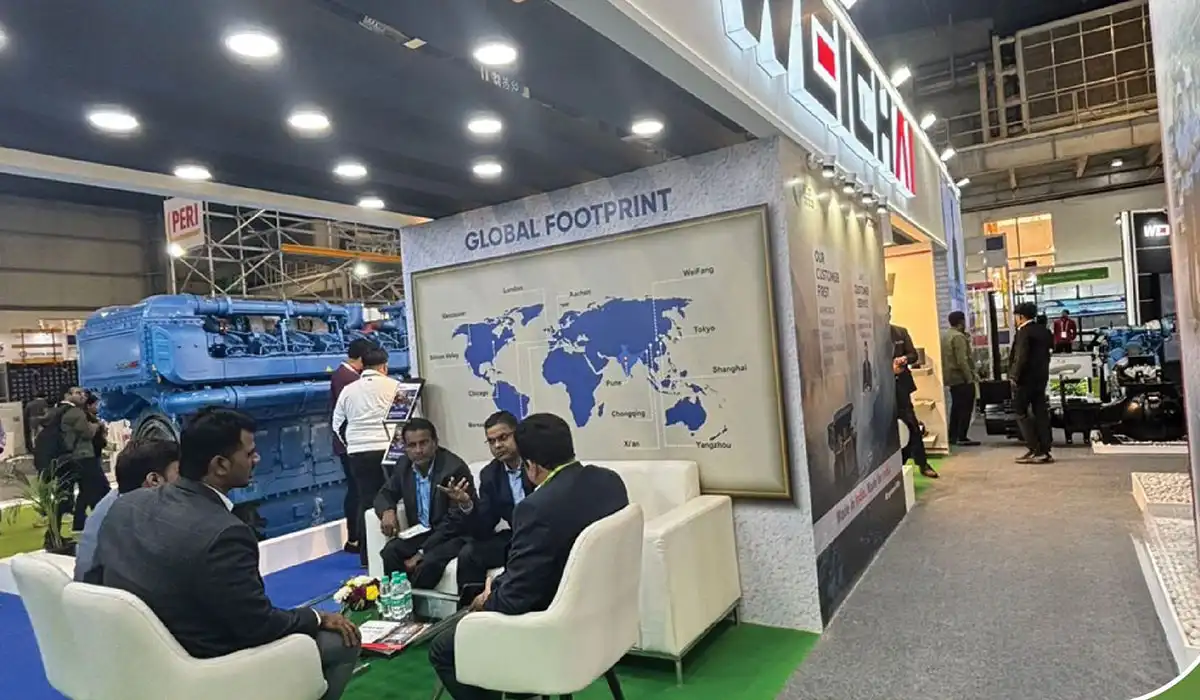

Weichai has a manufacturing plant in Pune, which is currently expanding to accommodate the production and testing of larger engines. While we previously lacked the necessary tests for these bigger engines, we are now in the process of installing a new test set. As an ISO 9001:2015 certified company through TUV Nord, we strictly adhere to all guidelines and conduct regular surveillance audits to maintain high standards of quality.

Regarding localization, we have achieved over 20% so far, primarily in peripheral components cooling system. In the past year, we made significant progress, especially in localizing the cylinder block, cylinder head, and fuel systems.