Behaviour of Ternary Concrete with Flyash & GGBS

Pradip Kumar Jha, Zonal Head (TASC), UltraTech Cement, Bhubaneswar, and Sunil Kumar Sharma, Head–Quality Control, UltraTech-RMC, Lucknow

Introduction

The Construction Industry has been facing challenges with regards to sustainability, disposal of industrial waste material, reduction in use of raw materials and energy requirement in cement manufacturing, reducing the carbon emission and rendering the environment cleaner, reduction in cement consumption in concrete, making durable concrete, thus, increasing the service life of construction etc.Extensive research in concrete technology for finding alternative materials which can partially or fully replace Ordinary Portland Cement (OPC) and which can also meet the requirements of strength and durability aspects still continues.

Industrial wastes containing cementitious properties such as flyash, GGBS, silica fume, metakaolin, Rice husk rash, etc, have been tried as alternatives to partially replace cement in concrete. The performance of such cementitious materials in terms of strength, workability and durability parameters have been quite promising, and have subsequently led to the development of binary, ternary and tertiary blended concretes, depending on the number of Supplementary Cementitious Materials (SCM) and their combinations used as partial cement replacement materials.

The SCM used in Ternary Blended Concrete, to some extent, has remained successful in meeting these objectives. Ternary concrete mixtures include three different cementitious materials. The use of appropriately proportioned ternary blends allows the effects of one SCM to compensate for the inherent shortcomings of another. Such concretes have been found to exhibit excellent fresh and mechanical properties. This evaluates the performance of concrete containing SCM like FlyAsh and GGBS with respect to fresh and hardened concrete of Ternary mixes.

This experimental investigation is aimed at evaluating the performance of concrete containing supplementary cementitious materials (SCM) like FlyAsh and Ground Granulated Blast Furnace Slag (GGBS). FlyAsh and GGBS are the cementitious materials that can be used in the production of long-lasting concrete composites.

Materials

- Cement – The cement in use confirmed to OPC 53 grade of IS 269:2015

- Flyash – The Flyash used in the study confirmed to IS 3812 (Part1):2013

- Ground Granulated Blast Furnace Slag – GGBS confirmed to IS 12089:1987

- Coarse and Fine Aggregates – The coarse aggregates and fine aggregates used in the study confirmed to IS 383:2016.

Experimentation

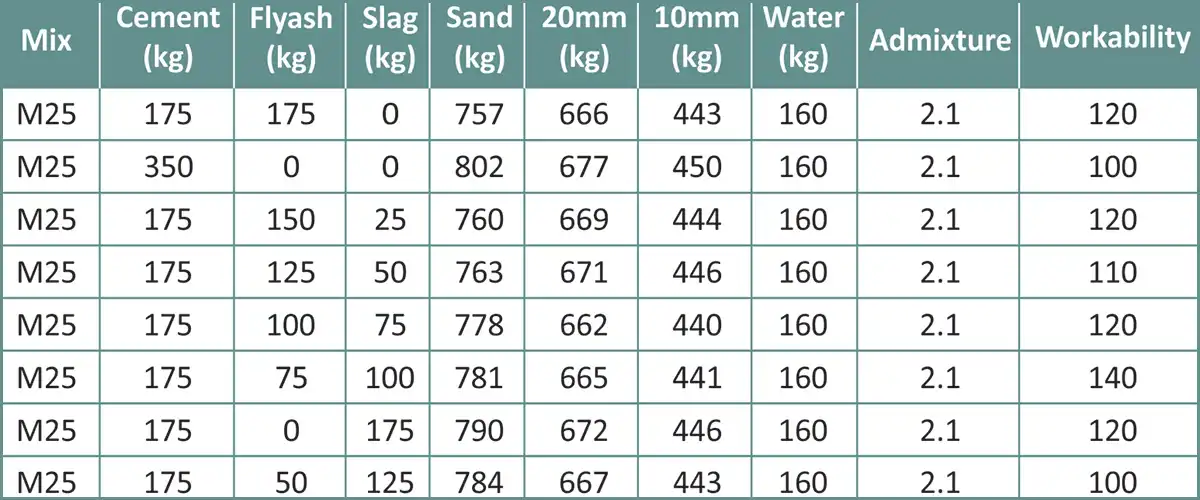

- Concrete mixes of M25 grade were prepared with different combinations of OPC, Flyash, and GGBS.

- The slump retention, final setting time, compressive strength values, and growth rate of compressive strength of these mixes were measured for 3, 7, 28, and 60 days.

- The compressive strength of ternary blended concrete (TBC) is compared with the Portland concrete and binary concrete.

- Aggregates (Fine, Coarse-10 mm, and Coarse-20 mm), Water, Admixture were kept almost same for all the different trial mixes.

- Admixture dosage was 2.1% by weight of Cement and Cementitious particles.

- The slump was maintained at 110 to 120 mm.

Results

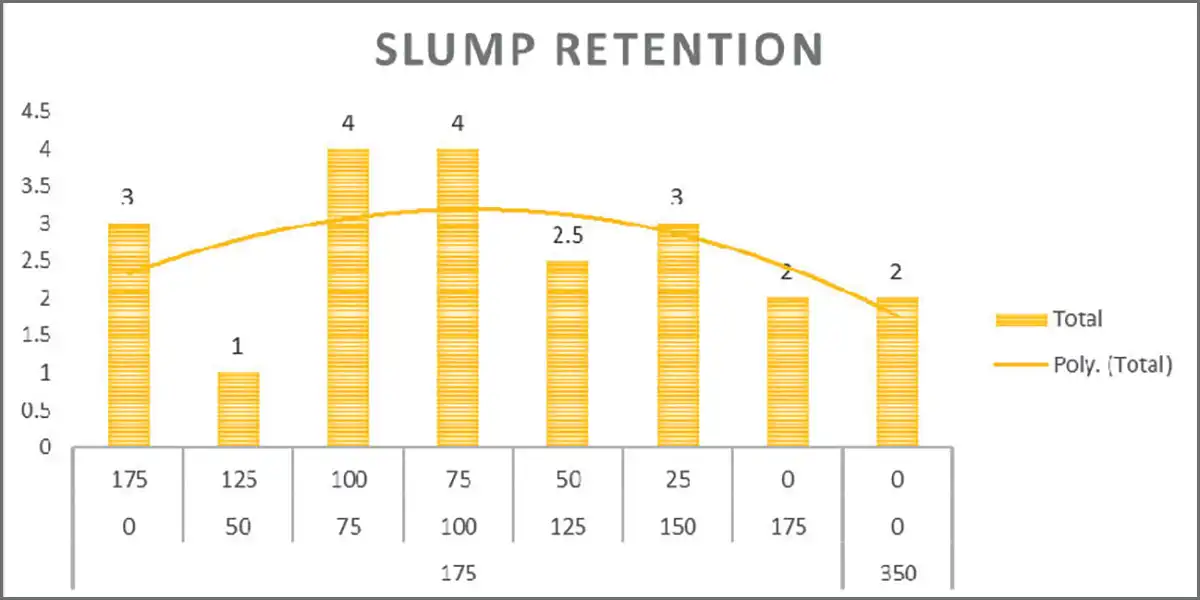

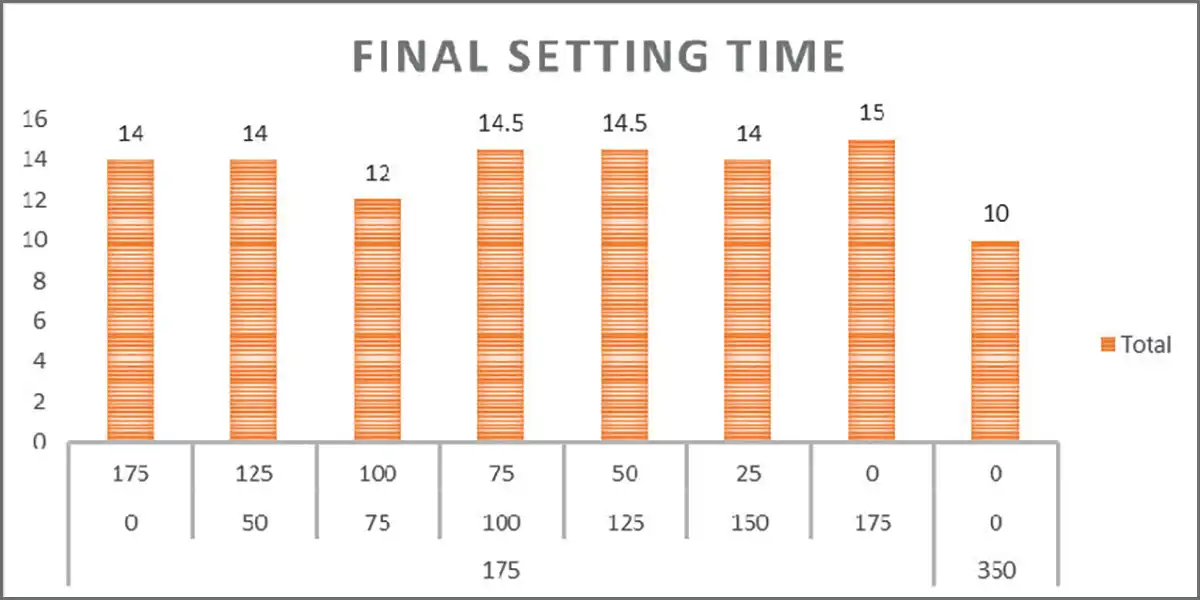

Slump Retention

Inferences

- The Slump retention time is the least for the Portland Cement Concrete.

- The Supplementary Cementitious Materials (SCM) contribute to the slump retention of ternary and binary concrete.

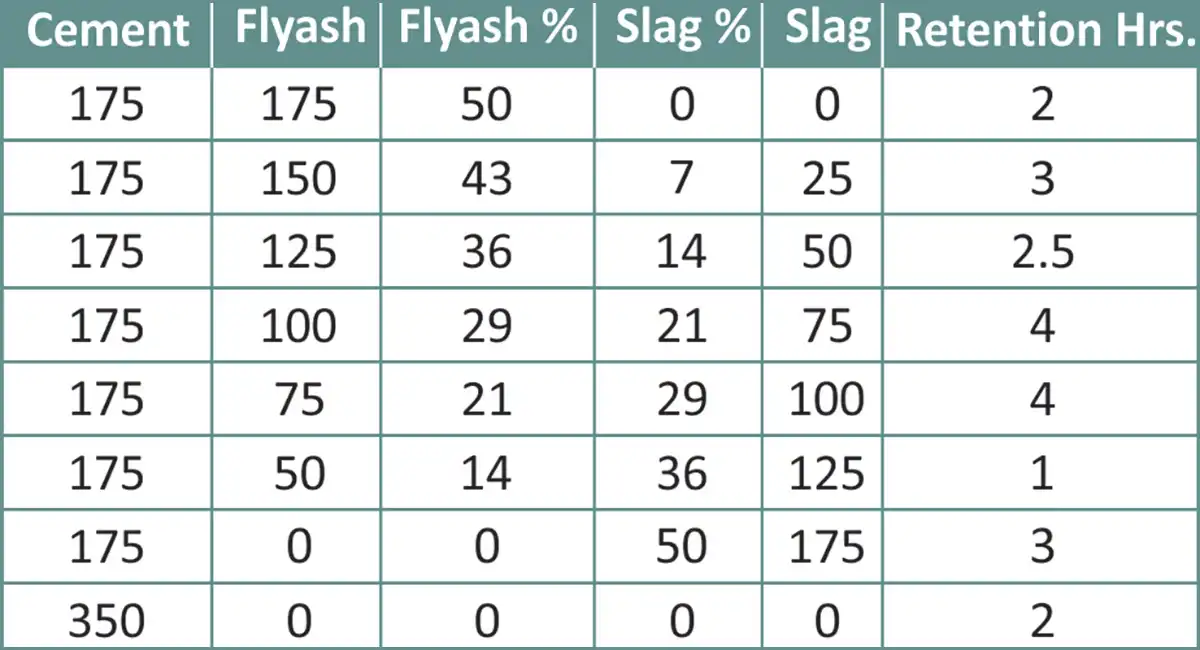

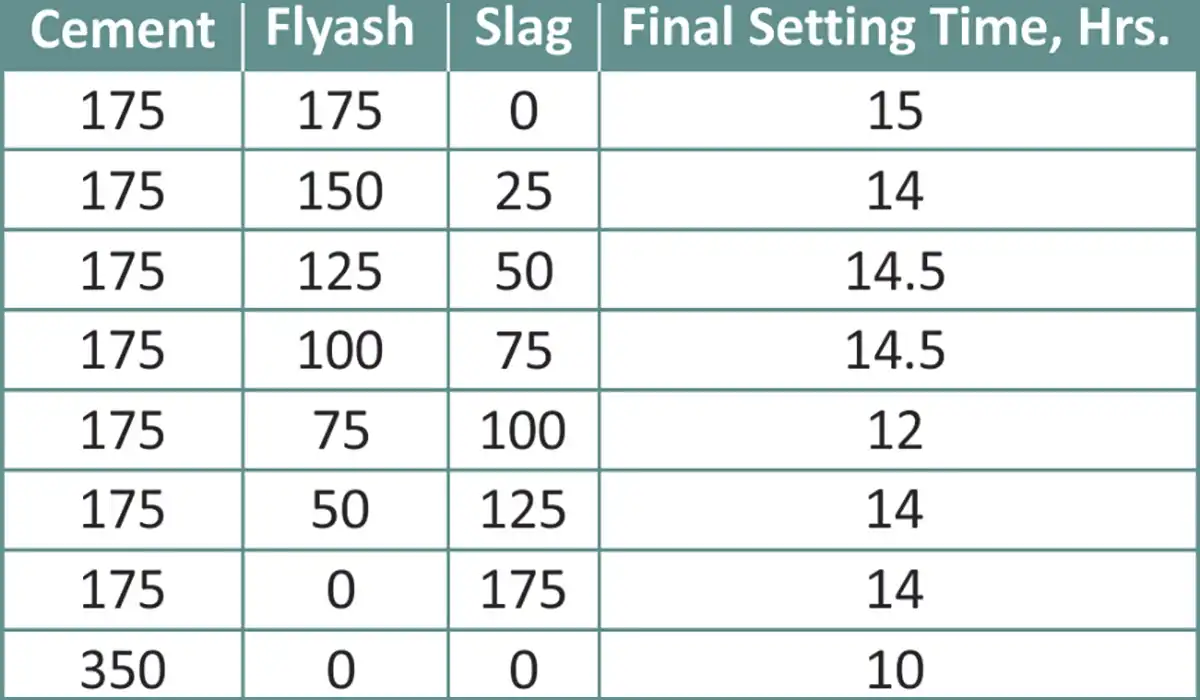

Final Setting Time

Inference

- The Portland Cement Concrete has the least/fastest Final Setting Time.

- Amongst the Ternary blended Concrete, the Final Setting Time of mix (21% FA + 29% GGBS) is the least.

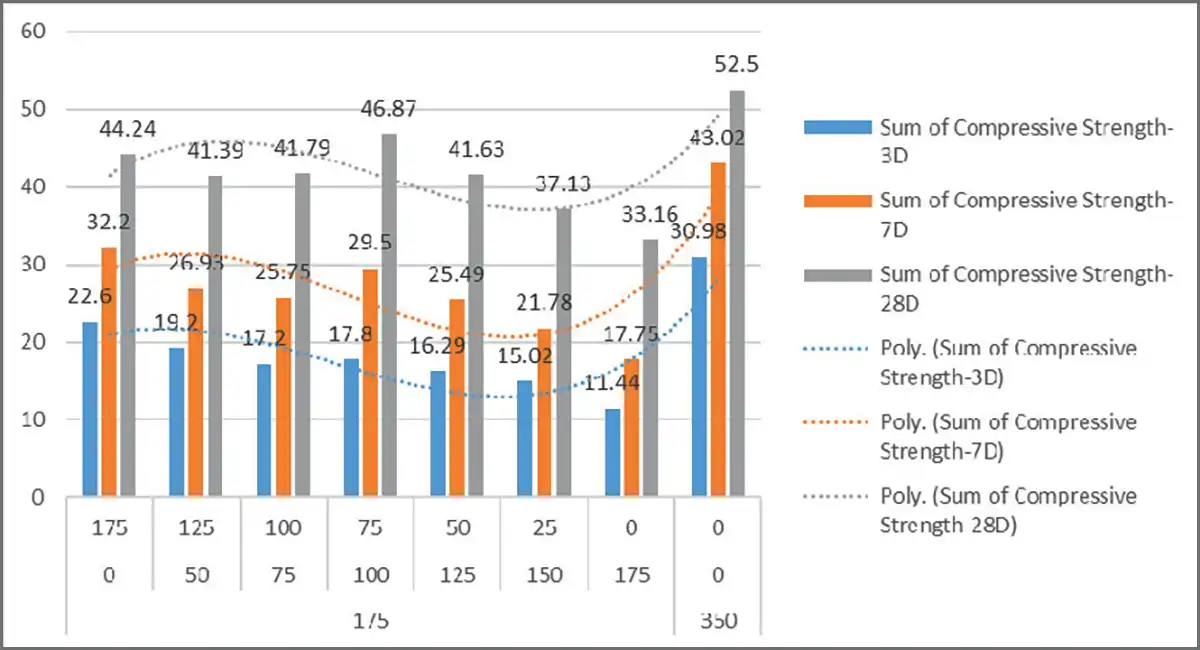

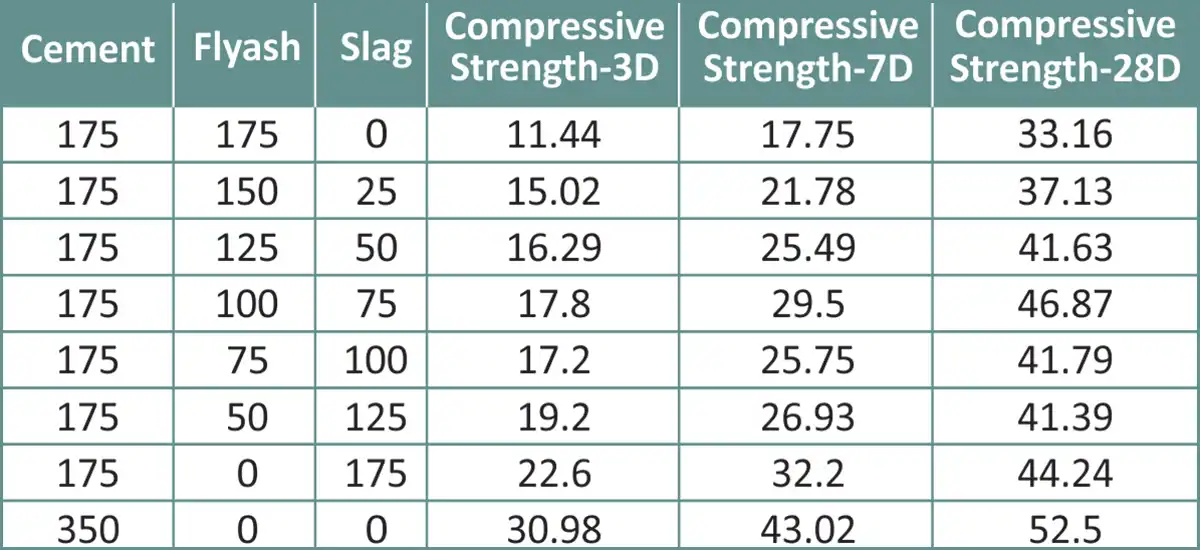

Compressive Strength

Inferences

- At 3 days, 7 days, and 28 days, the compressive strength of Portland Concrete is considerably higher than the Ternary Blended Concrete.

- As the percentage of FlyAsh goes on decreasing, and the % of GGBS goes on increasing, the compressive strength of the Ternary Blended Concrete goes on increasing. This holds good for compressive strength of the Ternary Blended Concrete at 3 days, 7 days, and 28 days.

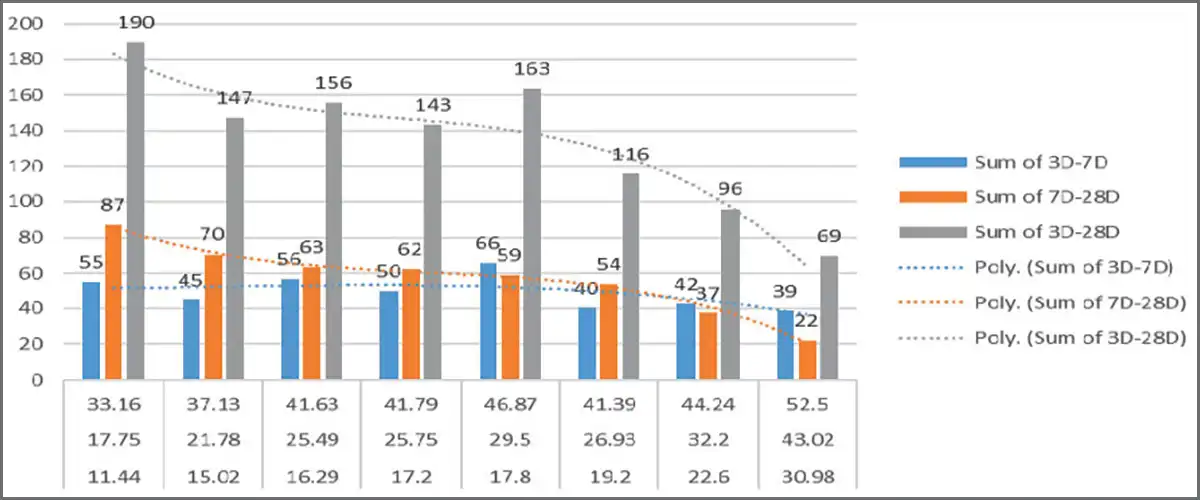

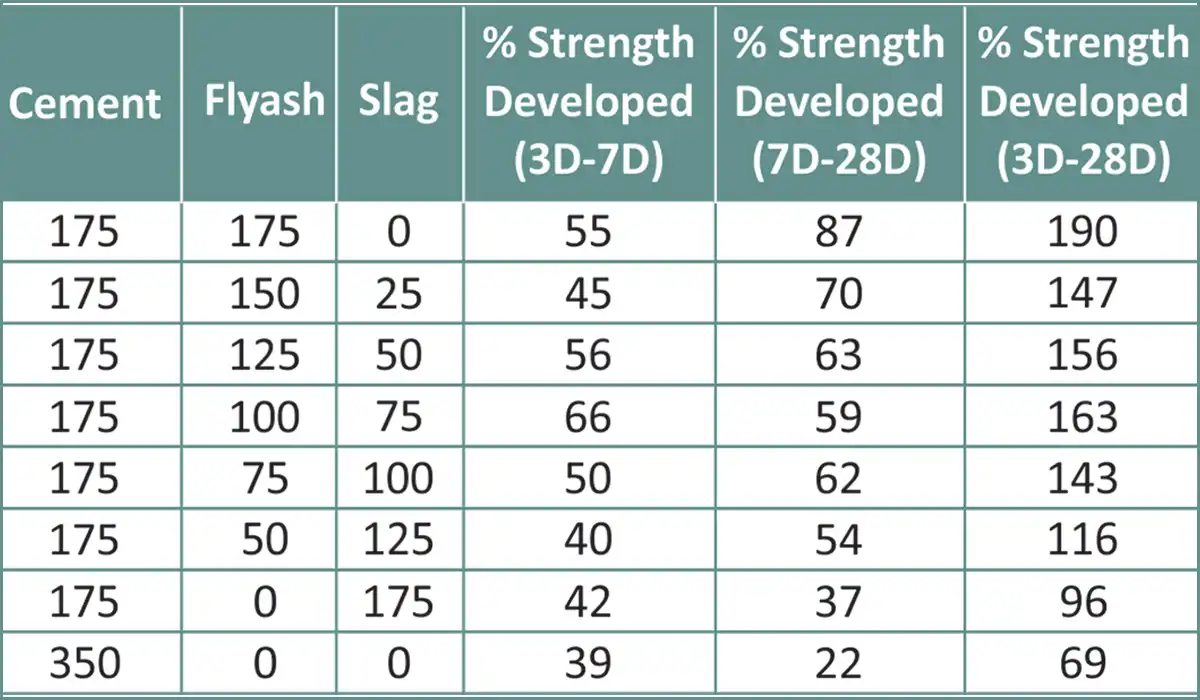

Rate of development of Compressive Strength

Inferences

- The rate of development of compressive strength in the TBCs is higher compared to the Portland Cement Concrete. This holds good for all the cases viz., strength development during the period of 3 days to 7 days, 7 days to 28 days, and 3 days to 28 days.

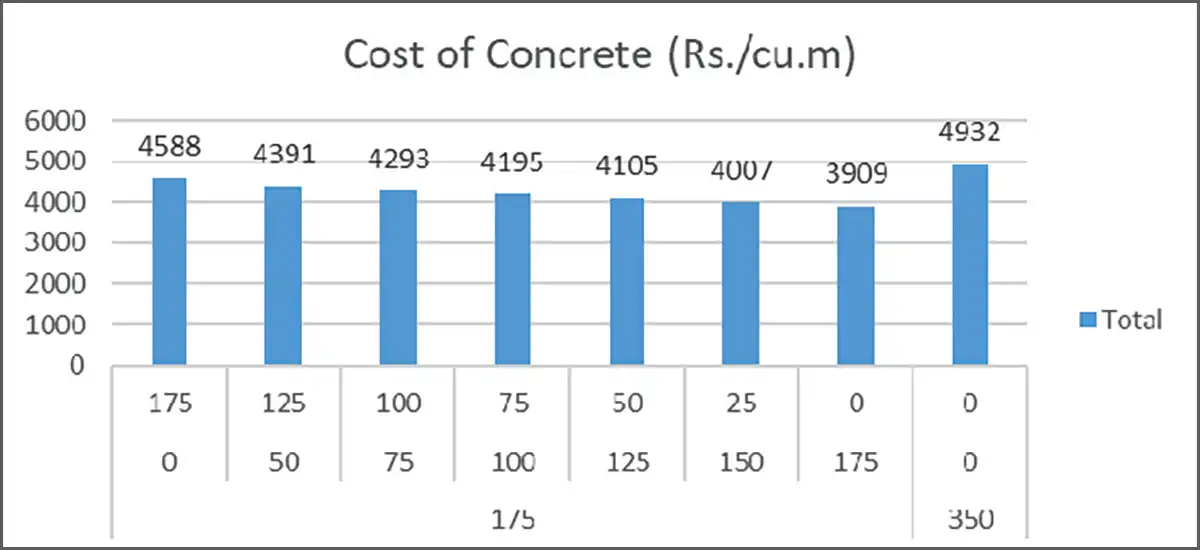

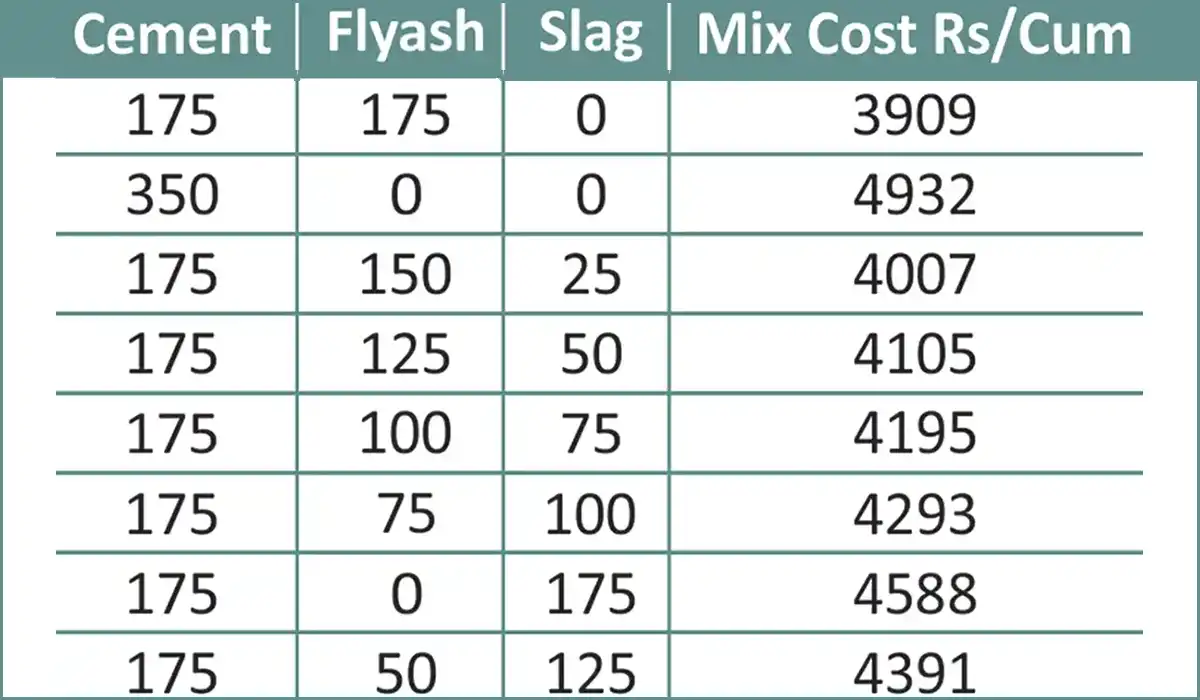

Cost of Ternary Concrete Mix (relevant to Lucknow)

Inferences

- As the quantity of flyash goes on increasing, the cost of concrete goes on decreasing.

- The cost of concrete with OPC is considerably higher than that of cement replaced with cementitious particles.

Conclusion

It was observed that Ternary Blended Concrete (TBC) mixes exhibited superior qualities like slump retention, and enhanced workability, whereas their compressive strength values were found to be less than that of the conventional concrete mixes. The compressive strength of Portland Cement Concrete was higher than the TBC while tested at 3 days, 7 days, and 28 days.It was also observed that the rate of development of compressive strength of Ternary Blended Concrete (TBC) was higher than that of Portland Cement Concrete.

The binary concrete has been in use for long. To utilise supplementary cementitious materials more effectively, and reduce their cost in the construction industry, ternary concrete is a viable alternative. With abundance of Flyash and GGBS in India, the relevance and acceptance of ternary concrete is going to be high.

Manufacture of ternary concrete will permit greater utilisation of industrial wastes and enable production of concrete with lower cement factor, leading to resource conservation, enhanced waste utilisation, and greater sustainability in concrete construction.

Published on:

Published in: ICCT, January- February 2024

Share:

We Value Your Comment