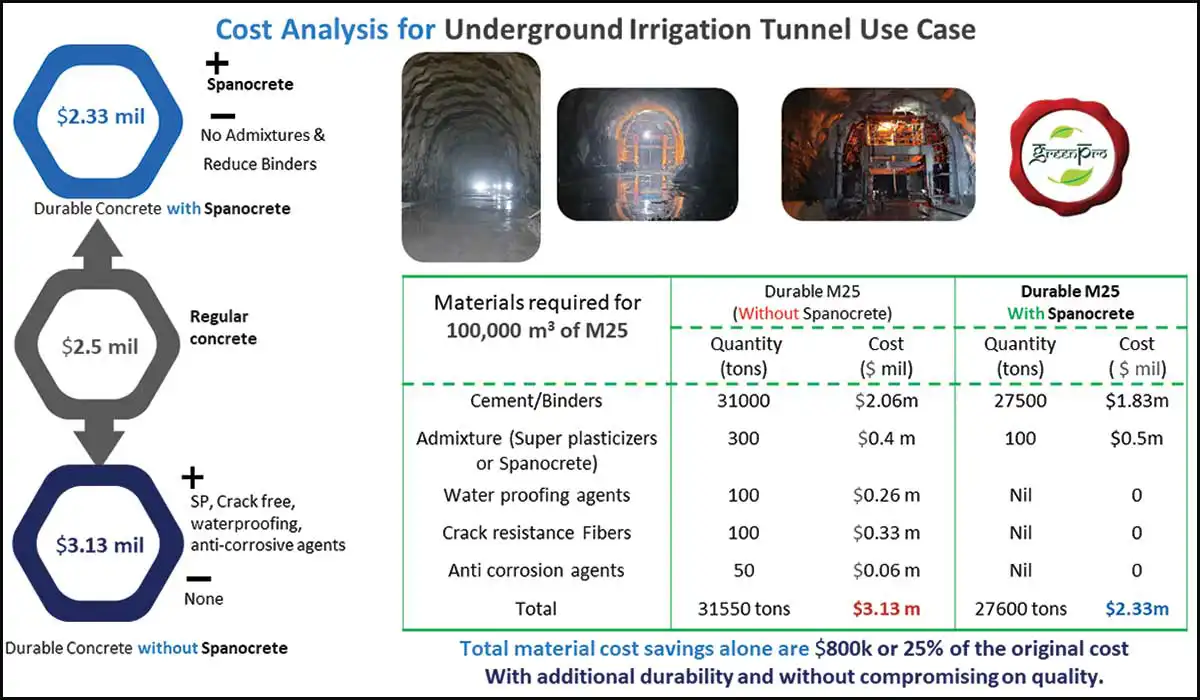

Nanospan's Spanocrete® Additive for Waterproofing & Leak-Free Concrete

Spanocrete has proven its mettle in the first massive Lift Irrigation project taken up by the Government of Telangana to irrigate one million acres in the State.

The scope of work for the construction company charged with this ambitious project was to construct a ‘D’ shaped twin tunnel with a diameter of 11.50 m and length of 18 km. The duration of the project was 30 months. The total quantity of earthwork will be 34,00,000 m3 (approx.), and concrete was 6,50,000 m3 (approx).

Challenges for the Irrigation Tunnel

An irrigation tunnel is usually constructed when the canal network hits a terrain which is challenging to cross (eg. mountains). Here, a tunnel boring machine (TBM) is not feasible and hence the drill and blast method is used to construct the tunnel. Once the tunnel is excavated, it has to be properly supported by laying precast concrete blocks, spray shotcrete to stabilize the vulnerable portions of the tunnel walls, and use lining concrete for extra support to avoid collapsing. In case of an irrigation tunnel, additional precaution needs to be taken so that the interior of the tunnel does not erode due to the salts in the water flowing.

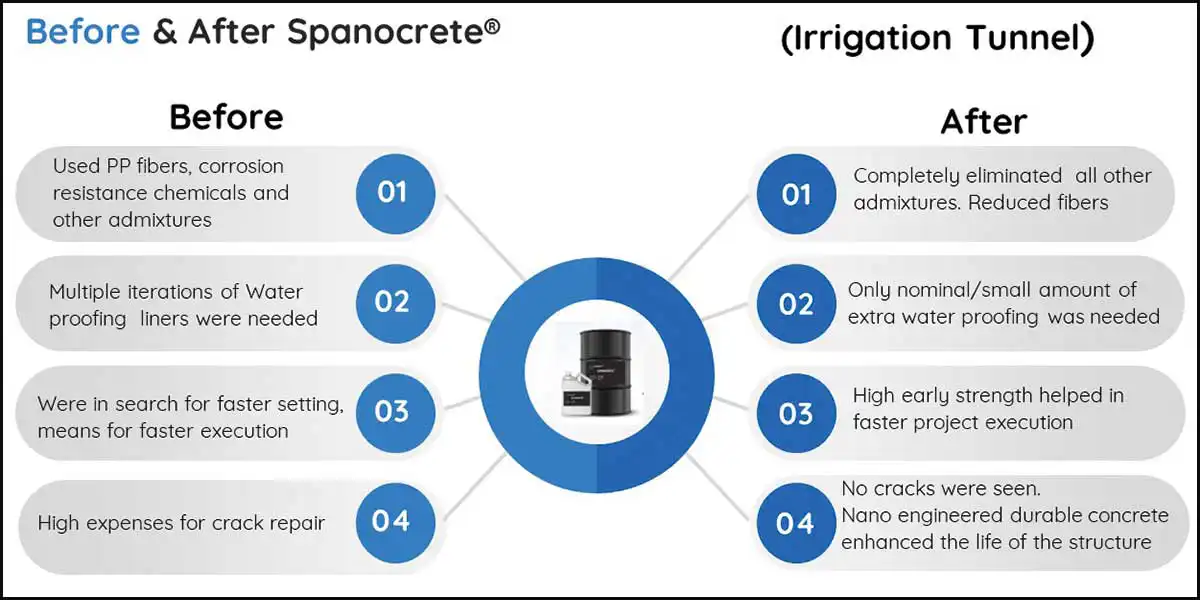

Existing approach

As a practice, to make the concrete good enough to support all the above required features, the following distinctive materials are added:- Fibers & Superplasticizers to increase the compressive and tensile strength.

- Waterproofing agents to avoid damage from flowing water.

- Corrosion inhibitors to reduce the wear and tear due to the salts in the water.

- Several more admixtures are mixed to keep the dry shrinkage, thermal and plastic shrinkage cracks at bay.

- To test all the combinations thoroughly for long term use.

- The cost increases as the number and amount of materials increase.

- Specialized expertise is required to handle the different materials and their combinations.

Spanocrete® is a Solution that meets all these requirements exactly due to its following characteristics:

- Spanocrete® is a first-of-its-kind, multi-functional, strong and durable, graphene-based admixture that produces nano-engineered concrete with crack-free, waterproofing, and anti-corrosive properties.

- It is an ideal additive for the construction of irrigation or water tunnels, canals, and storage dams where waterproofing and leak-free concrete is necessary.

- Spanocrete® is a single additive which can replace all the ala-carte admixtures and eliminate or reduce many secondary reinforcement materials employed for designing durable concrete. When added, it makes any regular concrete design into a comprehensively durable concrete.

Benefits realized for Irrigation Tunnel construction project

Nanospan’s Spanocrete® was successfully deployed in a stretch that involved of 75000m3 of concrete inside the irrigation tunnel. Spanocrete® brought the following benefits:- High early stage and later stage strength

- 10% reduction in binders without compromising the performance of the concrete.

- Eliminated the use of Superplasticizer, Waterproofing agents, Anti Corrosion agents, Crack Resistance Fibers and replaced with Spanocrete®.

Spanocrete Dosage: 1 kg/cu.m

Deployment results for Irrigation Tunnel concrete

Extensive testing with Spanocrete was done before qualifying it for its USP. Even with 10% reduction in binders, the compressive strength achieved at 7 days is 80% and at 28 days is 125%. All the other admixtures used for durability were eliminated.Please contact Nanospan at

Published on:

Published in: NBM&CW - April 2024

Share:

We Value Your Comment