ICRETE: A New-Age Material for Concrete

In the world of construction, breakthroughs that redefine how we build are rare but when they do occur, they revolutionize the industry. ICRETE is one such innovation. This engineered, patented additive is transforming the way concrete is produced and performs.

V. R. Kowshika, Executive Director, Amazecrete

ICRETE, based on a game changing technology, represents a shift from traditional concrete to intelligent concrete. By addressing corrosion at the micro-level, it ensures that infrastructure built today will stand the test of time. A scientifically developed solution, it is designed to elevate concrete’s capabilities across multiple dimensions. When incorporated into concrete, it offers the following benefits:

- Makes concrete more economical and sustainable, supporting eco-friendly construction.

- Enhances impermeability, thereby significantly improving durability and extending the lifespan of concrete structures.

- Reduces shrinkage cracks, a major contributor to structural deterioration.

Recent studies and real-world trials have further validated ICRETE’s potential demonstrating its ability to function as a corrosion inhibitor. It adds a powerful layer of protection to concrete, particularly in challenging environments, and boosts its long-term structural integrity. Extensive corrosion studies have been conducted to investigate the performance of ICRETE-incorporated concrete, and the results are promising. This innovation represents a significant step forward in building stronger, longer lasting, and more resilient infrastructure.

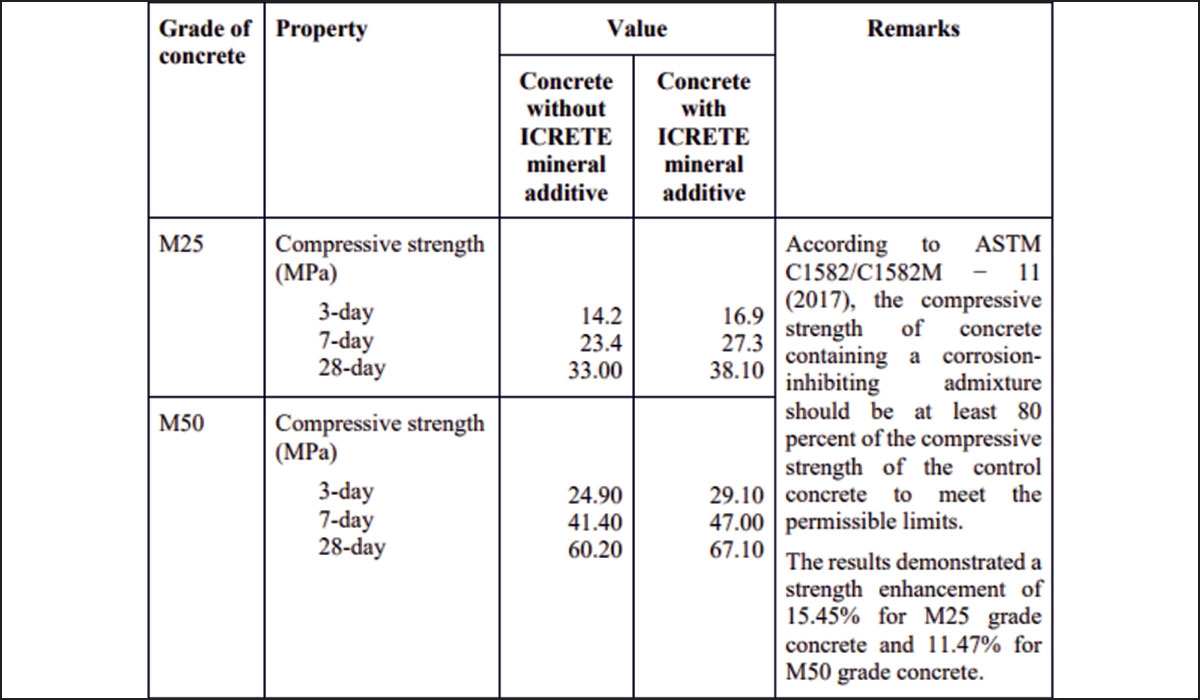

Enhanced Corrosion Resistance in Concrete Using ICRETE Mineral Additive

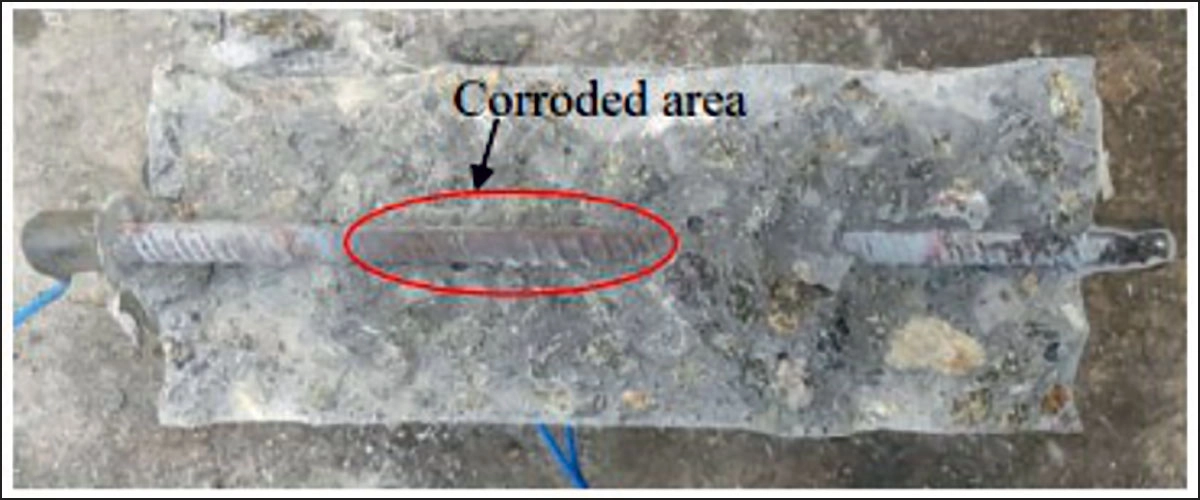

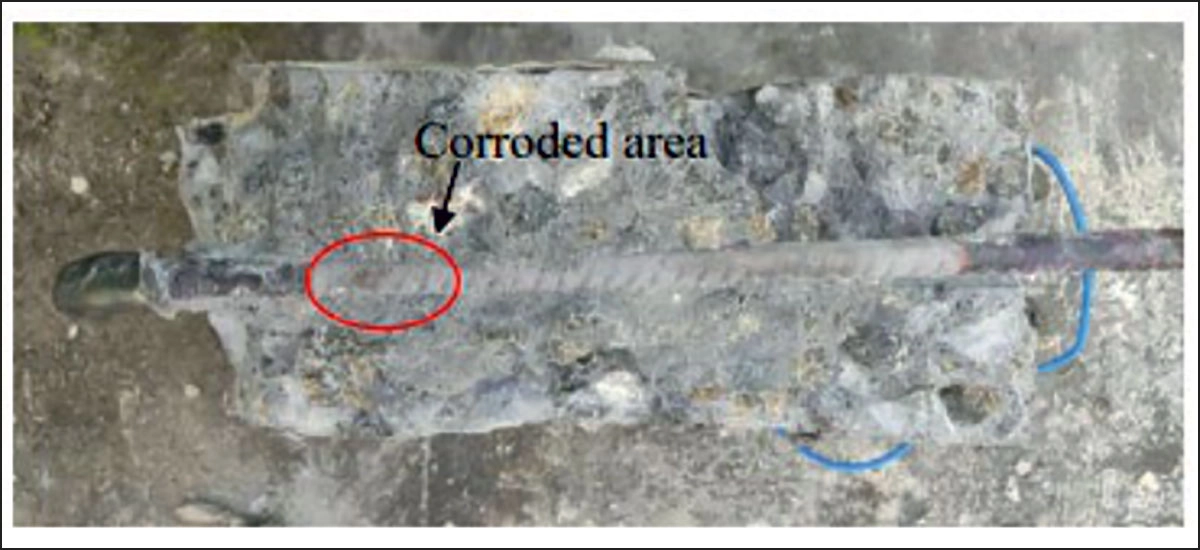

A detailed visual inspection revealed a significant reduction in corrosion on steel rebars embedded in concrete incorporating ICRETE mineral additive, compared to those in conventional concrete. This reduction in corrosion was consistently observed across both M25 and M50 grade concrete specimens. The presence of the additive proved highly effective in mitigating the corrosive activity within the concrete matrix, particularly by protecting the embedded steel reinforcement.

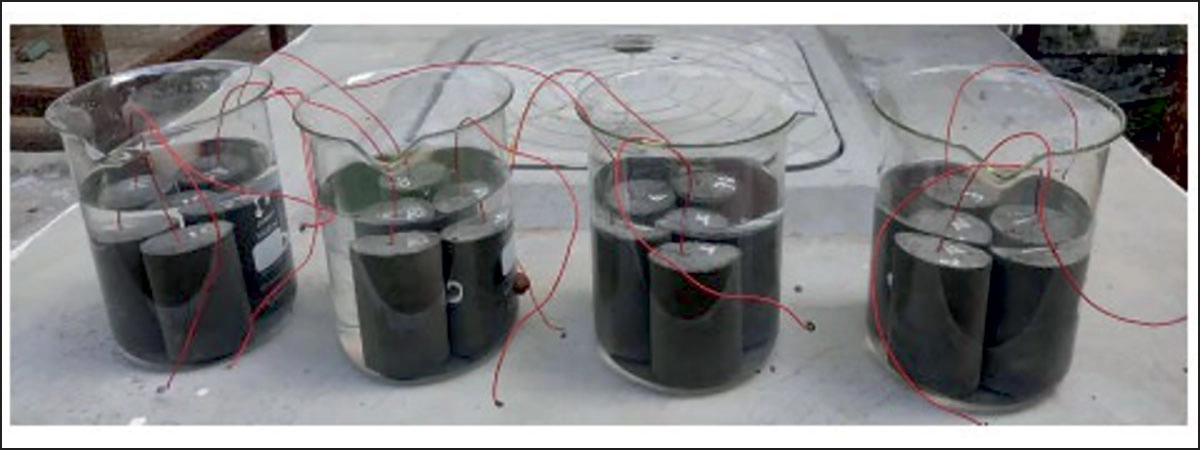

Figure 1: Steel rebar embedded in concrete cylinder

Figure 1: Steel rebar embedded in concrete cylinder

In M25 grade concrete, the corroded zones were visibly smaller when ICRETE was used. More notably, M50 grade concrete with ICRETE did not show any rust on the steel surface, even after full duration of the testing period. This exceptional performance can be attributed to the denser microstructure of M50 concrete, enhanced further by the protective characteristics of the ICRETE additive.

The combination of a refined microstructure and corrosion-inhibiting properties resulted in superior durability, making ICRETE-admixed concrete an ideal solution for construction in aggressive and corrosive environments. These findings underscore the potential of mineral additives like ICRETE in extending the lifespan and structural integrity of reinforced concrete structures.

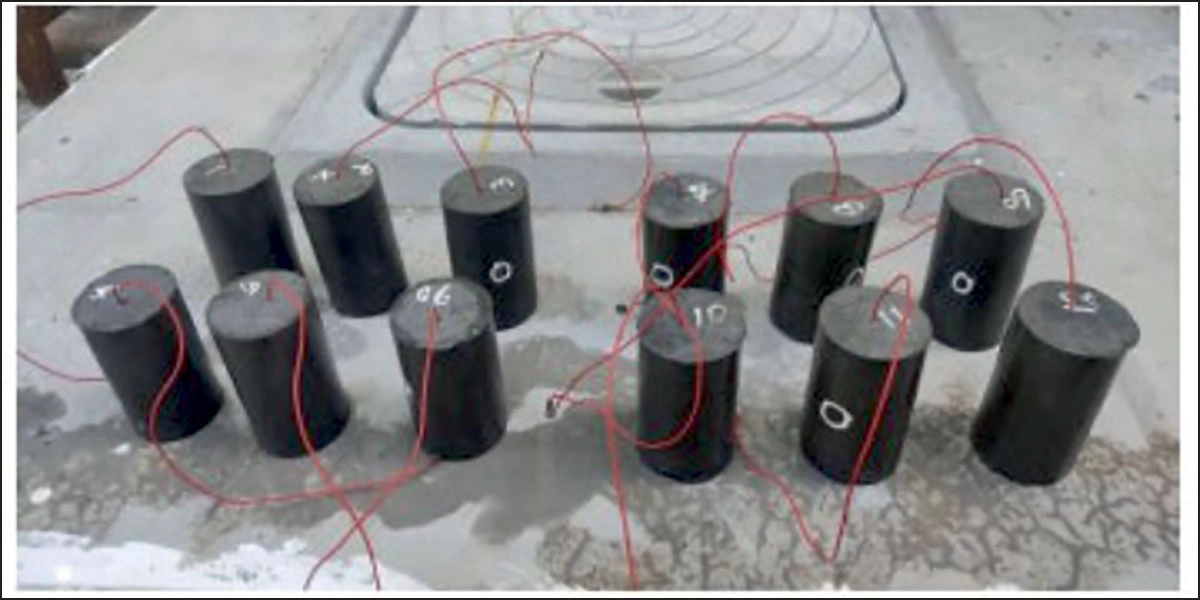

Figure 2: Typical view of concrete cylinder specimens immersed in 3% NaCl solution

Figure 2: Typical view of concrete cylinder specimens immersed in 3% NaCl solution Concrete cylinder specimens used for electrochemical studies

The study conclusively demonstrated the beneficial effects of incorporating ICRETE mineral additive into concrete mixes, particularly in terms of mechanical strength and corrosion resistance:

Features of ICRETE

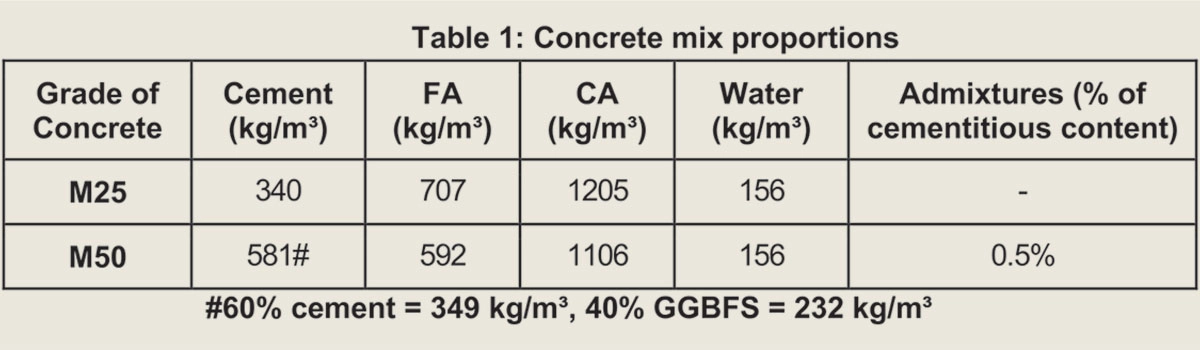

Enhanced Compressive Strength: The addition of ICRETE significantly boosted the compressive strength of concrete. Specifically, M25 grade concrete showed an improvement of 15.45%, while M50 grade concrete achieved an 11.47% increase, affirming the additive’s capacity to enhance concrete performance under load.

Superior Corrosion Resistance: ICRETE-admixed concrete exhibited a marked reduction in macrocell potential and integrated macrocell current in both M25 and M50 grades. These parameters indicate an improved resistance to corrosion, a critical factor for the durability of reinforced concrete.

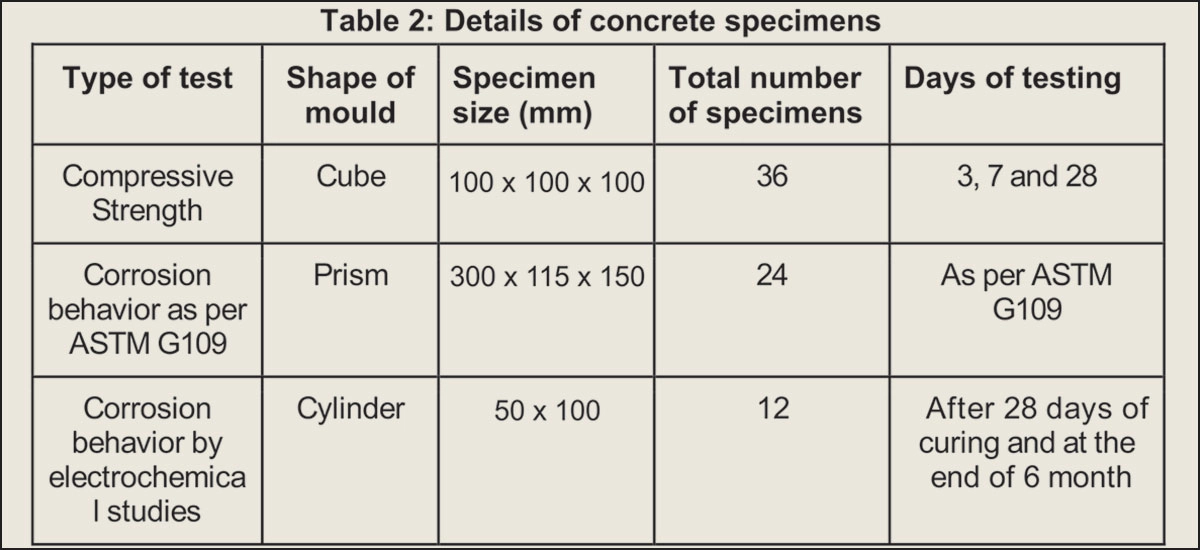

Table 3: Compressive strength

Table 3: Compressive strength

Reduced Corrosion Propagation: In control specimens (without additive), macrocell potential increased steadily over time—signifying the onset and progression of corrosion. In contrast, concrete containing ICRETE maintained consistently lower macrocell potential values, clearly demonstrating its effectiveness as a corrosion-inhibiting admixture.

Delayed Onset of Corrosion: The control samples recorded integrated macrocell current values exceeding the critical threshold of 150 coulombs after 119 days (M25) and 238 days (M50), confirming active corrosion. However, specimens with ICRETE displayed negligible current values for an extended period, substantially delaying corrosion initiation.

Figure 3: M25 grade concrete without ICRETE mineral additive

Figure 3: M25 grade concrete without ICRETE mineral additive

Improved Electrochemical Performance: Electrochemical evaluations further confirmed the protective nature of ICRETE. The admixture resulted in lower corrosion current density (icorr) and higher polarization resistance (Rp) when compared to conventional concrete, validating its role in enhancing corrosion resistance.

Protection against Harsh Environments: Given its dual benefits—mechanical enhancement and corrosion protection, ICRETE mineral additive is recommended as a reliable and efficient corrosion-inhibiting solution for reinforced concrete structures, particularly in marine environments and in areas exposed to chloride ingress.

Acknowledgement: The author thanks Dr. Ramkumar Natarajan, scientist and inventor of ICRETE for his continued support.

Figure 4: M25 grade concrete with ICRETE mineral additive

Figure 4: M25 grade concrete with ICRETE mineral additive

References

- ASTM C1582/C1582M-11(2017)e1 – Standard Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete, American Society for Testing and Materials (ASTM International), United States.

- ASTM G109 – 21 – Standard Test Methods for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments, American Society for Testing and Materials (ASTM International), United States.

- ASTM C876-15 – Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete, American Society for Testing and Materials (ASTM International), United States.

- IS 10262 – 2019 – Concrete Mix Proportioning – Guidelines, Bureau of Indian Standards, New Delhi.